Spring 2025 Newsletter

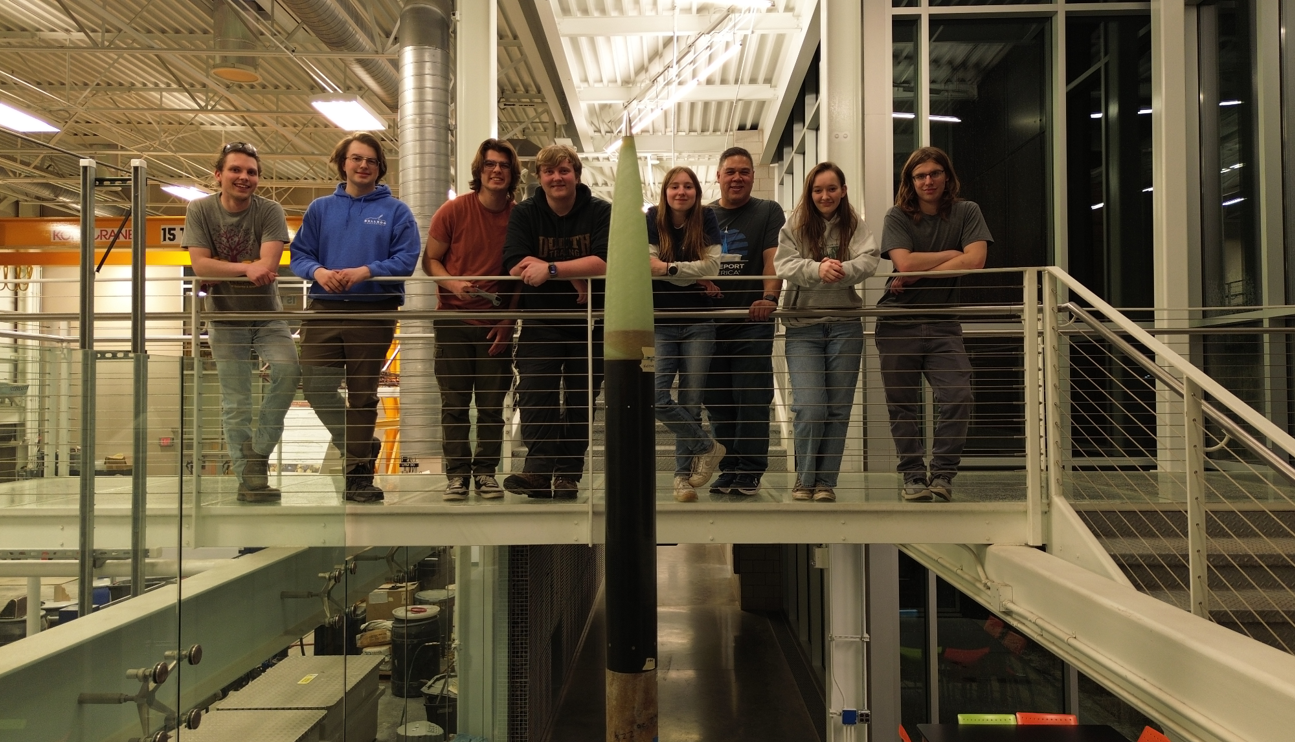

*rocketry members with the rocket

Our team has reached incredible heights this semester. As it comes to a close and our competition draws nearer, here’s another update from us!

Meet Our 2025 Competition Rocket!

The Airframe

The Airframe Committee, led by Josh Dolan, has been hard at work finishing this year's rocket airframe, which stands at 14 feet 8 inches tall with a 6-inch diameter. They have also been focusing on integrating components from other committees into the rocket and ensuring that all of the tubes fit together properly.

So far this year, we have manufactured two carbon fiber tubes for the forward and aft body sections. We also fabricated a fiberglass tube for our electronics bay and machined aluminum couplers and bulkheads to connect all of the tubes. Additionally, we purchased an aluminum tube to serve as our motor tube and a nosecone from Wildman Rocketry.

*anatomy of the rocket

The Payload

For our payload this year, we have developed a sensor capable of measuring the amount of fluid in a sealed container. The sensor turns the fluid into a capacitor—an electrical component that stores energy, similar to a battery—in order to generate a signal that indicates the fluid level. This technology is especially useful for measuring liquid fuel in zero-gravity environments like space, where many common techniques used on Earth are ineffective due to the fuel floating and clumping together.

*box constructed the team

The team has meticulously constructed a box for our sensor and circuit boards out of aluminum and stainless steel. The design includes modular shelves, allowing it to be easily adapted for different experiments and designs. Additionally, the box protects the experiment inside from electromagnetic interference and noise that could affect the performance of our sensor.

Check out a basic simulation of our circuit along with a more detailed explanation here.

Electronics

Ensuring a safe touchdown, rapid recovery, and live recording of the rocket launch during our competition is the responsibility of the electronics team. Our electronics system consists of two independent flight computers, a GPS tracker, rocket motor sensors, and a camera system.

Our flight computers, the Silicdyne Fluctus and the Featherweight Blue Raven, form a double-redundant system to ensure parachute deployment during descent. The camera system will utilize a DJI O4 Air Unit along with a Radix 2 HD, which serves as a drone flight controller. This video will be submitted to IREC’s live video competition. The GPS tracker is Entacore’s AIM XTRA, which allows us to track our rocket from up to 20 miles away. The final component of our electronics is the motor sensor. We aim to collect pressure data from our motor during launch at the competition, which will be fulfilled by the Altus Metrum EasyMotor.

Recovery and Separation Testing

Recovery System Development

The recovery committee, led by Ben West, has been working diligently to develop the recovery system, which includes the parachutes, connecting shock cords, and separation systems. Earlier this semester, they conducted a series of tests to ensure that our parachutes will function as needed, as well as to confirm that our rocket will separate properly to allow the parachutes to deploy at the right time.

*parachute

Parachute Testing

Parachute testing consisted of a particularly fun few days at the UMD farm, where we tested our parachutes’ coefficients of drag by dropping them from a heavy-lift drone. We conducted these tests to determine the appropriate parachute sizes to order for our rocket. From our results, we found that the parachutes had a drag coefficient of approximately 0.88—about the same as a skydiver. Based on these calculations, we decided to order 6-foot and 18-foot standard parachutes from Rocketman Parachutes. Check out one of our latest parachute drops in this video!

Separation Testing

This semester, the recovery team also conducted separation testing. In order for our parachutes to deploy from the rocket, we need to separate the rocket using black powder charges. The rocket will separate between the aft body tube and the electronics bay for the drogue parachute, which deploys at apogee. The main parachute will deploy between the upper body tube and the nose cone. See our separation testing in action here!

Outreach

First Robotics Competition: Northern Lights Regional

Our volunteers helped make sure that moving the high school teams' robots out of the building went smoothly. We were distributed across a few different roles, with responsibilities involving managing foot/robot traffic, scheduling each team a time to load out, and directing the drivers to the correct locations outside the building.

* volunteers

Volunteering for the 2025 First Robotics competition opened up opportunities for our team to make and grow our connections. As our own rocketry competition grows steadily closer, we have seen firsthand how much effort and dedication volunteer members put in for the Spaceport America Cup. Having the opportunity to put our own efforts and dedication into the First Robotics competition to help the events run smoothly puts our team in a position to understand what it takes to make a large event successful.

Upcoming Events

Rocket Reveal

Join us for our end-of-year event on Saturday, April 26, from 1:00 to 4:00 PM as we celebrate the dedication and innovation behind our 2025 IREC rocket! This is our moment to showcase what we've built, reflect on a year of hard work, and recognize every member who made it possible. The event will feature our CEO, Rachel Cirillo, and Chief Engineer, Andrew Ludwig, discussing our rocket, along with a poster session detailing the various components that made it a success.

* rocket reveal

International Rocket Engineering Competition

For the past seven years, our team has competed in the International Rocket Engineering Competition. This year, we will be traveling to Midland, Texas.

The competition will take place from June 9 to June 14. We have spent the past year designing, building, and testing our 1-stage dual deployment rocket.

We will be competing against 160 other teams from all over the world in the 30k Student Research and Design category. We are very excited to compete with our rocket, Voyageur.

Support Bulldog Rocketry

Fuel the Journey: Give to Bulldog Rocketry

If you would like to make a financial contribution to our team to help support our members, follow the link below! Every donation helps us continue our mission by allowing more students to gain the valuable experience of traveling to Midland, Texas, where they’ll not only have the opportunity to launch a rocket but also connect with over 150 international student teams and industry-leading companies sponsoring the event.

* rocketry team picture